We believe green really is the new black, so we're pioneering a local, low carbon supply chain based on regeneration and circularity to make sure all our bags are ‘green’ no matter their colour.

Greenhouse Gas Emissions

We are committed to achieving net zero greenhouse gas (GHG) emissions by 2035. This commitment encompasses both the GHGs we emit directly and those associated with our business activities, referred to as Scope 1, 2 and 3 emissions.

Whilst we work towards our net zero target we will continue to invest in renewable energy and nature-based carbon offsetting solutions, such as forest restoration through the Woodland Trust and World Land Trust.

Our UK factories, which produce more than 50% of our products, have been carbon neutral since 2019.

Energy Reclamation

Our strategic partner, Muirhead, a member of the Scottish Leather Group, has a cutting-edge thermal energy plant, unique in the leather industry, that enables them to convert solid waste to steam, circularising the manufacture of our leather.

Their innovative take-back scheme converts end-of-life leather into fuel for their thermal energy plant, so that old leather contributes to the manufacture of new. That’s why we’ll still buy back any Mulberry bag that’s reached the end of its life, and by using Muirhead’s innovative energy reclamation technology, we can ensure its recovered energy becomes part of our circular supply chain, powering the production of a new Mulberry bag.

Dr Warren Bowden, Chartered Environmentalist

Dr Warren Bowden is a Chartered Environmentalist and the Scottish Leather Group's Sustainability and Innovation Director. A Fellow of the Society of Leather Chemists and inventor of the pioneering and patented Thermal Energy Plant, Dr Bowden has spent the past 15 years of his 25-year career in the sector leading the “drive to zero” and circularising leather manufacture.

“I think a bag could save the world if it is produced in a grass-fed, sustainable way, net zero sourced and recovered at the end of its life.”

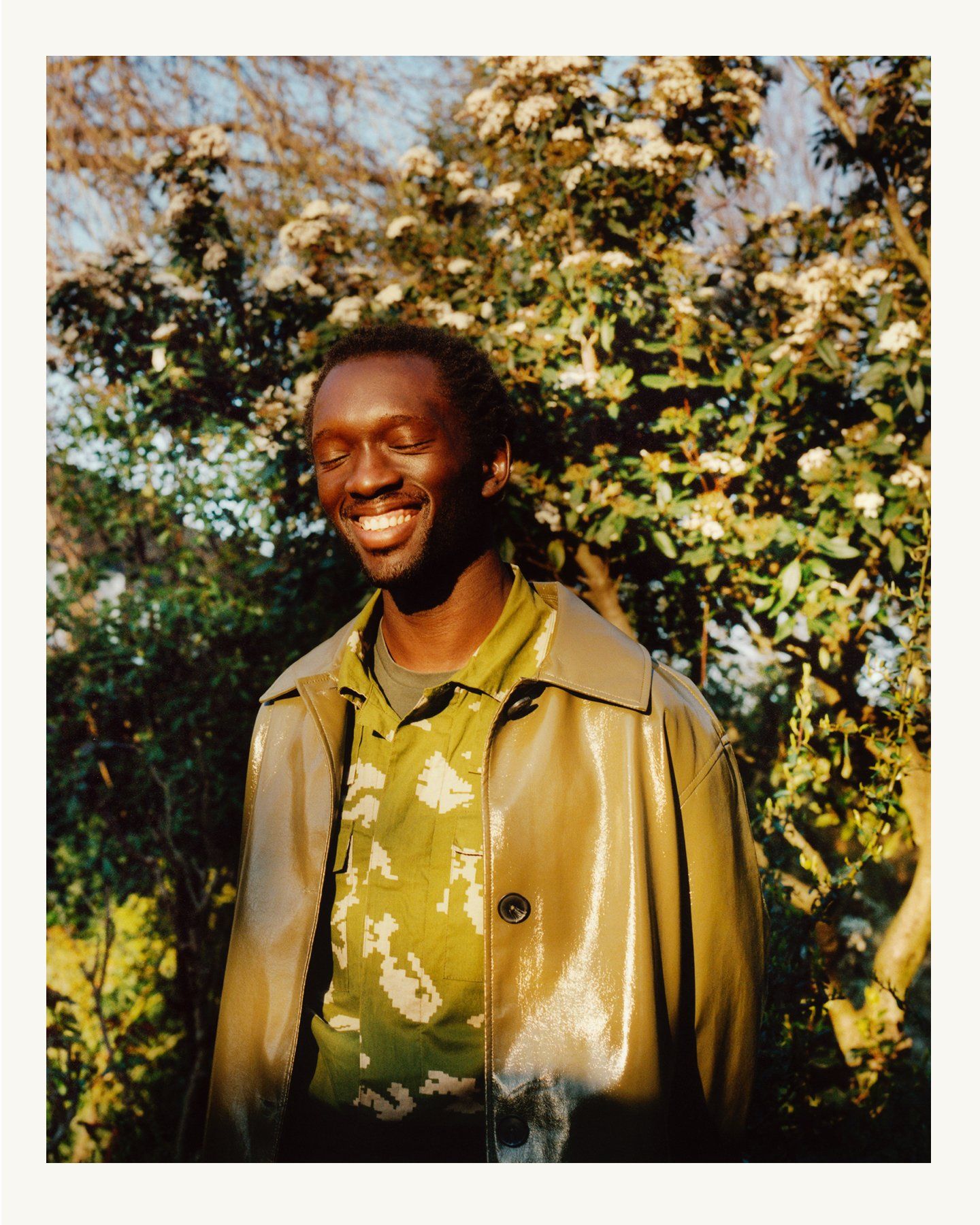

Wilson Oryema, Artist, Writer & Entrepreneur

We began our partnership with Wilson Oryema when we launched our first Made to Last event in February 2020, celebrating our commitments with a specially-commissioned poem on circularity. This artist, writer and entrepreneur has long been an advocate of sustainability and regenerative practices in fashion, and his work often explores human consumption, its effects on human behaviour and the planet.

“What constitutes more sustainable consumption is more considered thought, just taking the time to really think about an action or choice. What brands can do to make products more sustainable is really just, again, asking questions at every step of the process.”

Low Impact Materials

Mulberry collections are free from virgin nylon, which we have replaced with a sustainable alternative: the innovative ECONYL® fibre. ECONYL® is a durable and lightweight regenerated nylon crafted from fishing nets and other salvaged waste. It can be remoulded and recycled again and again, creating a closed loop regeneration process.

Our heritage Scotchgrain material has been a key part of collections for decades, and we’re proud to say it is now sustainably crafted with innovative Bio-Synthetic materials. This eco-friendly material repurposes inedible cereal waste to recreate the same hard-wearing, lightweight characteristics of our cult-status luggage.

We also feature bio-acetate frames in our eyewear collection. This biodegradable and recyclable cellulose material is gained from renewable resources such as seed fibres derived from cotton, and wood fibres derived from conifers and deciduous trees. The sunglasses also feature nylon bio-lenses, a material derived from the castor plant.

We’ve set a goal of using only sustainably sourced cotton in our collections by 2025. As signatories of the Textile Exchange’s Sustainable Cotton Challenge, we pledge to source this cotton through organic and recycled sources, or through our membership of the Better Cotton Initiative.

Waste

Our manufacturing techniques involve careful pattern placement to ensure minimal leather offcuts are produced for every bag we craft. We work with Scrapstore to supply waste materials to local schools, universities and craft groups – enabling our local communities to make something beautiful with high-quality materials that might otherwise go to waste.

Our Somerset factories also work with Zero Waste to Landfill providers, recovering energy from waste which cannot be reused. Our ultimate goal is to be completely Zero Waste throughout our operations.

Choyu, Influencer & Model

Choyu is a tattoo artist, surfer and influencer who has attracted a dedicated following for her eco-conscious fashion and lifestyle content. She speaks about the sustainability of her wardrobe with the same passion as the sea – her posts are as likely to involve styling her favourite Portobello and Alexa silhouettes as weekends spent on beach clean-ups.